Suzuki plots VVT update for Hayabusa

By Ben Purvis

Motorcycle Journalist

21.08.2023

Suzuki’s legendary Hayabusa turns 25 next year and has already diced with discontinuation once – having been dropped from the European market at the end of 2018 only to return in revamped form in 2021. Now new patents show the company’s engineers are working on a variable valve timing system for the Busa that could both extend its life and add more performance.

Launched in 1999, the Hayabusa has been through three distinct generations in terms of its styling but it’s been a process of evolution rather than revolution. The bare frames of a current 2023 model, the 2008-on middle generation and the 1999 original are visually all but identical, and while the engine has been tweaked – growing from 1299cc to 1340cc via a 2mm increase in stroke in 2008 – it’s still very much the same design.

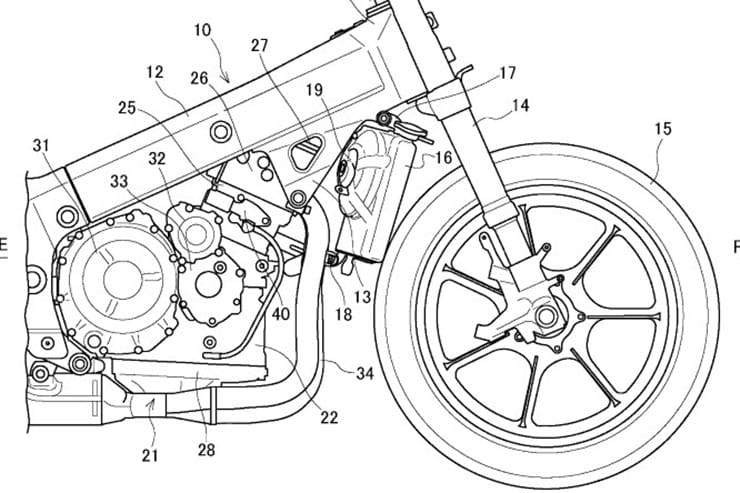

The new patents for a Hayabusa with variable valve timing show a continuation of the same thinking, adding the VVT system to the existing bike while avoiding expensive redesigns of major parts like the frame. Despite its legendary status, the Hayabusa isn’t a huge seller, so such an approach makes sense, minimising R&D expenditure while ensuring substantial improvements in performance, emissions and economy.

You can read our full review of the 2021 Suzuki Hayabusa inc. video and owner reviews here.

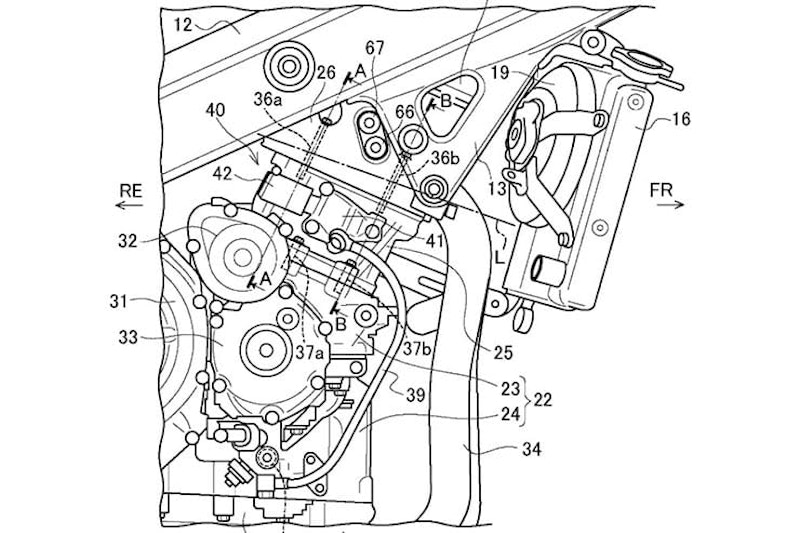

Variable valve timing is already a well-known idea, and the version shown in Suzuki’s patents isn’t revolutionary. It’s a simple, hydraulic cam-phasing system, on the intake camshaft only, that can rotate the intake cam by a few degrees in relation to its sprocket when oil pressure is introduced to the cam phaser. It’s done at high revs, advancing the intake camshaft timing to increase the amount of valve overlap – the period when the intake valves are open to allow a new charge of fuel and air into the cylinder, but the exhaust valves are also still open to expel the spent charge from the previous cycle.

Lots of valve overlap is advantageous on high-revving, high-performance engines, maximising the amount of fresh fuel and air filling entering the cylinder and making sure all the exhaust gets out. However, with fixed valve timing, the same amount of valve overlap is excessive at low revs, allowing unburnt fuel to escape into the exhaust before the exhaust valves close and harming both emissions and economy.

The emissions element is particularly important, as under Euro5 rules there are tight limits on non-methane hydrocarbon emissions – which are the result of unburnt fuel in the exhaust.

We’ve already seen several bikes with cam-phasing VVT to solve the problem, including several Ducatis using the company’s DVT system. Going further back, the Kawasaki GTR1400 used a similar cam-phaser as long ago as 2006, and Suzuki itself has dabbled with cam phasing VVT, using an innovative, all-mechanical system on the most recent generation of GSX-R1000 that was introduced in 2017. That setup, while cleverly avoiding hydraulic or electronic elements (and hence skirting race regulations, for instance in MotoGP, that ban electro-hydraulic VVT) lacks the computer-controlled precision of a hydraulic VVT, and hence Suzuki has long been working on a hydraulic VVT system for the GSX-R1000.

Since the Hayabusa VVT system seen in the new patent application is so conventional, you’d be right to wonder what is actually likely to be patentable in Suzuki’s design. The answer appears to be a specific detail of the actuation system, achieved via a computer-controlled actuator that opens or closes oil channels to the cam phaser.

Normally, this actuator would be mounted on the cylinder head near the cam phaser, but to do that with an evolution of the existing Hayabusa engine, Suzuki would be forced to redesign the frame where it wraps around that part of the engine, adding substantially to the bike’s development costs. So, as described in the patent, the actuator is moved down and bolted to the side of the cylinder block, where they don’t interfere with the existing bike’s chassis design. Internal oil passages run through the cylinder block to the cylinder head to feed the cam phaser, but an external pipe feeds pressurised oil to the actuator from the oil pump so there’s no need to alter the engine’s cases or bottom-end design.

Essentially, the idea is to add variable valve timing benefits while minimising the amount of expenditure on new components and the tooling to manufacture them. That, in turn, means there’s less cost to be amortised once the bike is in production, reducing the cost to the customer.

The cost cutting design shouldn’t do anything to reduce the usefulness of the VVT. Like other cam-phasing systems it will do the job of altering the intake camshaft’s timing to maximise torque and minimise emissions and fuel consumption at low revs to ensure compliance with regulations. But at high revs, the timing can be advanced to maintain that efficient operation across a wider rpm range, boosting outright power. Power has always been the Hayabusa’s signature, and the fact that the third generation, Euro5-complient version that was launched in 2021 has less of it than the second-gen bike (even though it’s improved delivery means quicker acceleration) is something that VVT could easily resolve.

If Suzuki’s VVT system makes production on the Hayabusa, it’s not going to be for the 2024 model. That bike has already been launched in some markets, including a ‘25th Anniversary’ edition that’s so far been added to the range in the USA, France, Italy and Germany sporting orange and black paintwork and special badging to mark the model's quarter-century.

If you’d like to chat about this article or anything else biking related, join us and thousands of other riders at the Bennetts BikeSocial Facebook page.

Share on social media: