Inside the mind of the Kawasaki H2 SX designer

By John Milbank

Consumer Editor of Bennetts BikeSocial

29.11.2017

Based on the H2 and H2R, this supercharged sports-tourer makes 197.3bhp @ 11,000rpm and 101.3lb-ft @ 9500rpm. Taking ram air into account, Kawasaki claims a whopping 206.5bhp! BikeSocial spoke to Juichi Oyanagi, the stylist of the incredible new Kawasaki H2 SX.

Who is the target rider of the H2 SX, and how does the machine fit in the range with the Z1000SX?

As Kawasaki, we are always trying to provide an exciting product. The Z1000SX is still a successful bike with a sporty, touring feel to suit the customer’s mood, but after we introduced it, we realised we had something quite unique, and thought that we could take it to the next level.

We expect some Z1000SX owners will step up to this model, and maybe some others might be looking for even more performance than that offers. We’re also aiming at customers looking at European machines, like the KTM SuperDuke GT and Ducati Multistrada – customers who are performance orientated, but also want to tour.

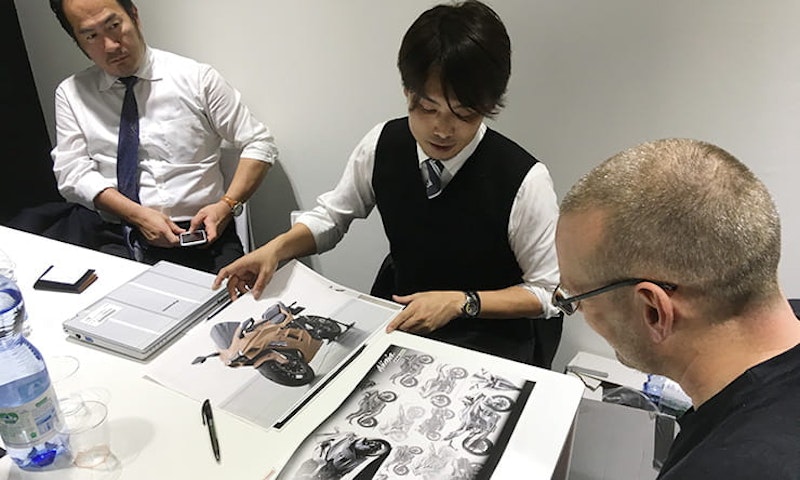

Kawasaki designer Juichi Oyanagi (middle) explains the work that went into creating the supercharged sports tourer. Keishi Fukumoto (Senior Manager, styling and design Dept) sits to the left

How do you find the balance between the creativity of design, and the limitations of engineering?

As a designer, it starts with sketches – lots of ideas – but ultimately of course not everything is possible due to engineering, cost, resource and time. From the beginning, we discuss with the engineers and financial teams to find the best way to make the machine possible, and to please the customers, which of course is more important. The balance between pricing and features has to be good, which is why at the ideas stage we’re already collecting a lot of information on what can be theorised.

There’s a 5kg limit to each of the two panniers – was it a difficult balance between making a high-performance bike and allowing for luggage capacity?

It’s one of the headaches we always have. When we talk about touring, customers often expect three cases – panniers and a top box – but on this bike you can only have the side cases. To add a top case would have meant needing a stronger sub-frame, which would have been bulkier and heavier.

If this had been a purely touring bike we could have done it, but as we’re putting quite a high priority on the sporty aspect, we need a good balance between the weight of the bike and its load capacity.

Are there any implications for servicing, maintenance and reliability in a supercharged engine?

This bike has the same engineering standards as the road-legal H2, and we really don’t see many issues in having a supercharger – the maintenance schedules are quite similar to a ‘standard’ engine, and there are no specific additional items to check. [It’s different on the H2R of course, but that’s more highly tuned.]

This bike makes more torque than the H2 – how did you achieve that?

The impeller shape in the supercharger is different, as are the fuelling settings and the gear ratios. From the beginning the concept was for touring, so we defined the important customer requirements – the engine characteristic needed to be quite different to the H2, so the engineers drew the ideal power curve, then tried to find the best solutions to achieve it.

Were there any points where the design and engineering teams came to blows over compromises?

One point was perhaps the fairing – I wanted to have more parts in the structure, which would have given more freedom to the design, but ultimately we needed to reduce the complexity. The muffler also – I always want to make that as small as possible, but from a performance, noise and emissions point of view, we needed some volume.

What other motorcycles have you designed?

My career in Kawasaki has included the Ninja 650, 300 and 200SL – I was in charge of those.

How do you start designing a bike like the H2 SX? Where do you begin?

In all of our product range, it’s always in our minds that Kawasaki bikes must be aggressive. We typically start with an engineering base, then give it a Kawasaki ‘kick start’. Some details will come from the basic elements given by the engineers, like castor and wheel angle, then we’ll work around these.

Is there any give and take in this process – can you move things the engineers have done?

Yes – this happens every day. As I look at the engineering drawings I’ll see things that we want to alter, so I go to the engineers to fight [laughs]… negotiate. But it also works the other way around, with the engineers coming to me to alter parts of the design, asking “why don’t you make this a little bit different!”

I’ll draw tons of sketches, and put them up on the wall. Then Keishi Fukumoto [Senior Manager, styling and design Dept] will come into the room and say “okay, this, no” [laughs]. He has to decide, from the sketches, which will be the final design, before the engineers are invited to look at the feasibility, which takes about two to three months. Then the mocks-ups are made.

After that we build a running prototype for the test riders – from there all the feedback from the riding experience comes into it, and we work again to further improve the design.

Is there a bike you really want to design next? What would you create given free reign?

I’m still too busy to think about my dream bike really, but I have some ideas for the next model I’m working on, and want to evolve what I’ve done here…

Share on social media: